Project Manager for BUILT and recent work with partner 1248 Holdings

Video

Using the DIRTY-branded prefabricated solution, BUILT creates customizable, floor-to-ceiling solutions that allow for growth and flexibility, integrated IT and electrical infrastructure within walls and speed to market that is unparalleled with conventional interior build solutions.

See our work – all videos located at vimeo.com/builtinterior

An Evening Conversation with Healthcare Leaders

How the healthcare industry joined forces to discuss healthcare construction as we emerge from one of the industry’s most tumultuous years in recent history.

Redefining Healthcare Design

Sneezing. Coughing. The cries heard ’round the world that result from ever-dreaded vaccinations and shots. Private conversations between a patient and a doctor. News that a patient doesn’t want anyone else to hear.

We’ve all heard these muffled and sometime not-so-muffled sounds as we’ve coughed, sneezed, waited for our own vaccinations, and as we’ve whispered our own vulnerable questions to trusted doctors. If the walls of hospitals, doctors’ offices, and healthcare facilities could talk, they’d tell stories of heartbreak, celebration, healing, and comfort. But it’s fair to say that those stories aren’t for the walls’ to share.

As healthcare facilities navigate this new decade and all that came from the most recent year, the need for patient-focused facilities has become an important topic of conversation. The need for adaptability, technology, innovation, and privacy.

The need for those stories that belong with the patient alone to stay with them. The need for walls that can keep a secret.

“It’s important to design these walls in healthcare facilities in a way that isolates sound as much as possible,” says Jeff Teel, Director of Acoustics at Henderson Engineers.

Confidentiality and privacy in healthcare construction starts with design.

“During design, especially at healthcare facilities, the sound isolation between areas can be very important for speech privacy and for patient confidentiality,” says Teel.

When walls are designed and assembled off-site, like in prefab construction, designers and contractors are able to begin with the end in mind. Unlike drywall that’s installed onsite, these prefab walls are designed using DIRTT’s proprietary ICE software. This software translates CAD and BIM/Revit to DIRTT, and these details translate factory data into installation instructions, which can be cut down to 1/16” of an inch, resulting in less sound transmission.

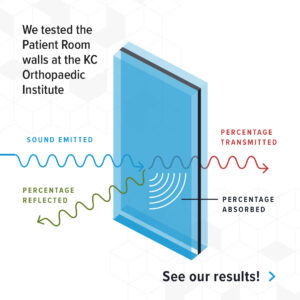

Sound transmission is measured by STC, or Sound Transmission Class, and is defined as the rating of a wall’s ability to block sound as it travels through the air. The higher the number, the quieter the walls.

Acoustical consultants like Jeff Teel perform field testing that measures the STC rating of a wall. You can watch a recent test Jeff performed for our client, Kansas City Orthopaedic Institute, here.

Because walls like DIRTT’s modular assemblies are designed and assembled offsite to a 1/16” of an inch, they typically carry higher STC ratings than traditional construction. For example, the walls we tested in the patient room at the Kansas City Orthopaedic Institute received a 50 STC rating, meaning loud speech on the other side of the wall is barely, if at all, audible.

2020 caused almost every industry to change, and change quickly. The healthcare industry has always experienced the need to adapt and change, but the past year has accelerated those needs and brought even more questions that need answers.

THE ACOUSTIC TEST RESULTS USING DIRTT WALL SOLUTIONS

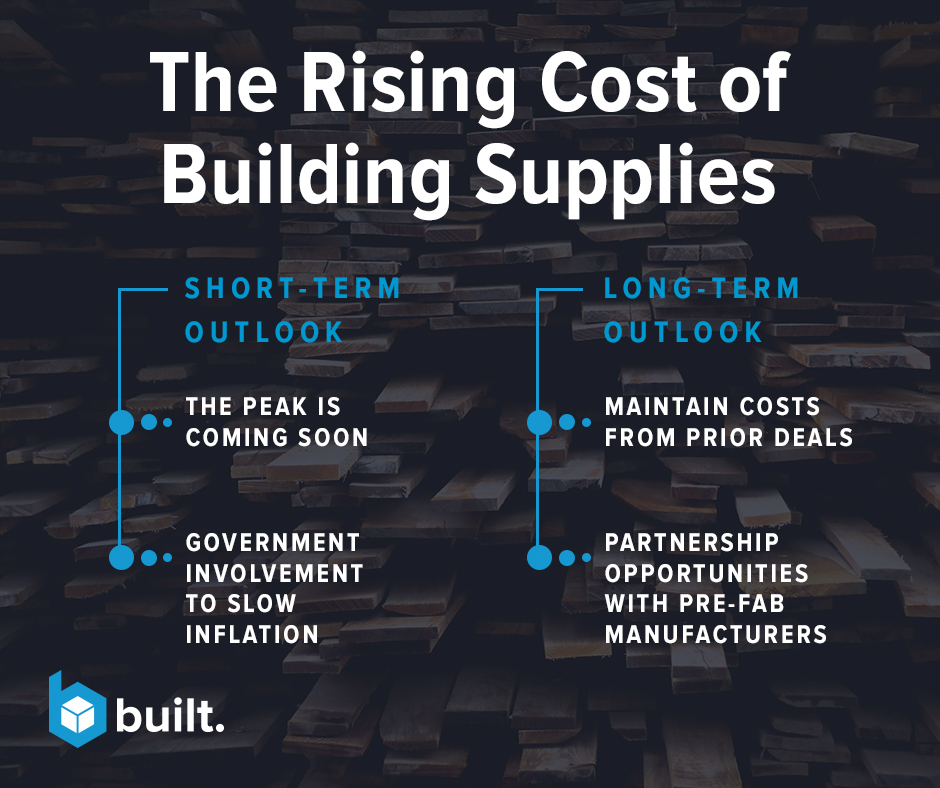

The Rising Cost of Building Supplies

Challenges bring opportunity, and today’s construction industry is no exception.

The construction industry looks wildly different today than it did before COVID. From labor shortages to price escalation, the changes have impacted everyone involved.

When asked about the rising prices of materials in the construction industry, Todd Missel, Vice President / General Manager at PARIC Corporation, answered, “I think what we failed to recognize is that the market had a surprise for us in terms of material escalation coming.”

In 2020, the industry hit a stopping point. Missel explains the drastic, swift changes, “Investors and developers got cold feet regarding their deals. Lenders did as well, and most of us experienced between a 20 and 30 percent decrease in revenue, nearly overnight.”

Though the revenue took a hard and fast hit, other changes hit much later.

A year after COVID began, the price of lumber increased by 300-500 percent. The raw materials industry was, like most other industries, impacted by staffing shortages. And those shortages created problems on both the supply chain and material delivery side of commercial construction, resulting in steep price increases.

Along with the price increase of supplies, companies were scrambling to forecast project intake of projects as pent-up demands and other factors were resulting in never-before-seen influxes of projects. Before COVID, construction companies could gauge staffing bandwidth and product availability based on the time of year, but post-pandemic opened a floodgate.

Sherri Balmer, Business Development Executive at PARIC Corporation expresses that from the construction end, “There’s a need to continue things along. The horizontal construction is picking up so fast that we have to work hard to keep up with it.”

Now, commercial construction operates at an even faster rate. While the pandemic forced people to stay home, the projects keep picking up. The more time people had at home, the more time they spent considering home renovation projects.

With a shortage of supply and labor and an increase in prices, construction businesses are realizing they need to think ahead and lean into nontraditional construction methods.

As Missel looks ahead to the next five to ten years, he expects clients will want to know more about maintaining deal costs.

And he sees this challenge as an opportunity for those working in prefabrication construction. Missel explains that prefab construction companies will be able to “use those principles of production from manufacturing to drive waste out of our supply chains, which will help drive value into projects. And we seek those partners who are willing to think outside of the box.”

Prefabrication companies were already thinking and performing with today’s solutions in mind before the pandemic even began.

Balmer expands on the path forward with the right partners. “We can come in as a team with PARIC and Built and educate them on what we can provide as a team and help them have an understanding of what this means on the ROI in the long run,” states Balmer.

HEAR THE CONVERSATION